Before you begin

Before spending money on insulation, sort out draughts.

Seal around doors and windows, block off unused chimneys and remove downlights that are not rated “close abutted” (downlights with air gaps around them).

Remember you still need to air or ventilate your home to prevent damp accumulating and to maintain air quality. Even on the coldest nights, you need to introduce some fresh air.

Consider getting independent advice.

If you are unsure about how best to insulate your home, consider booking a free visit from an Eco Design Advisor.

You will receive an independent assessment of your home. They’ll also recommend the most cost-effective ways to improve your house's energy efficiency and reduce power bills.

Building Code requirements

The minimum requirements for energy efficiency in house design and construction are spelled out in the Building Code's energy effectiveness clause H1. The standard AS/NZS4859.1 sets the testing and labelling requirements for insulation materials used in the home and whether they comply with the requirements of H1.

R value ratings

Heat travels from warm to colder areas. The resistance of a material or building structure to transferring or conducting heat is expressed as an 'R value'. Insulating materials with higher R values reduce the rate of heat loss (or gain in summer) from a building.

The R value depends on the type of material, its density and thickness.

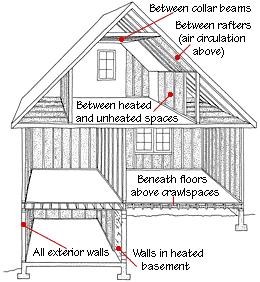

The required R values for insulation varies depending upon where it is to be placed in a house, the location in New Zealand and the house construction type.

The tables below show the minimum R values for wall, roof, floor and glazing required in different parts of the country for non-solid (timber-framed) construction houses.

Note: R values in New Zealand are in metric units (m² °C /W). R values in the United States are in imperial units, and look much bigger. Divide US values by 5.68 to convert them to metric.

Beyond the minimum

If you're building a new home, we recommend insulating beyond the code's minimum requirements. For a little extra cost, you can get a much higher level of comfort and health, and save on energy bills. In particular consider walls, roof, or underfloor areas that will be inaccessible once the house is complete. You won't get another chance.

Home insulation materials

Expanded polystyrene

Expanded polystyrene comes in rigid foam sheets. It is used for exterior cladding systems (monolithic cladding), and for insulating under concrete floors. It can also be used to insulate floors, walls and ceilings.

If there is a reasonably high working space under your house, it's relatively easy and safe to install polystyrene sheets between the floor joists.

Expanded polystyrene must be manufactured specifically for insulating as it requires compressable edges to make a tight fit against joists.

Glass fibre

Glass fibre (glass wool) is one of the most common insulation materials. It contains recycled glass and comes in a roll ready to run out in a roof space, or cut into segments for fitting between the framing timbers in your walls or ceiling. Various thicknesses are available for use in walls, ceilings and under the floor.

Glass fibre came under the spotlight some years ago after it was classified as a possible cause of lung cancer by the International Agency for Research on Cancer, part of the World Health Organisation. The agency has removed this classification and now considers glass fibre not classifiable as carcinogenic to humans.

However, it can cause irritation to the skin, eyes, nose and throat during installation. Always wear gloves, dustmask, goggles and overalls when handling glass fibre insulation.

Professional installation may not cost a lot. Glass fibre bought from retail outlets can be a lot more expensive than if you hire an installer and take advantage of their trade rates.

Glass fibre cuts easily with a craft knife and can also be pulled apart. When installing do not compress and make sure joins are butted together firmly to avoid reducing the R value.

Loose fill insulation

Loose fill insulation is most commonly machine-blown into ceiling spaces. Macerated paper (cellulose fibre), glass fibre and mineral wool (rock wool) are the most common. New or recycled wool is also used.

Loose insulation is installed by experts using specialist equipment. It is easier and quicker to install than blanket types, and is a good way of getting insulation right into every nook and cranny in a difficult ceiling space. But some types can be dusty and messy, so it's really not suitable if you use the ceiling space for storage.

Macerated paper, made from recycled newsprint, is the cheapest insulation available. A fire retardant is added during manufacture to prevent ignition. Although it is low-cost, macerated paper has earned a poor reputation in the past. Manufacturers tell us that problems have been overcome - but it is dusty, may retain moisture from roof leaks, and may settle or blow around over time. Rats like paper-based insulation! It may not be available in parts of the country.

Mineral wool is likely to be more expensive than macerated paper but will not blow around so easily, isn't dusty and won't burn. It will settle over time.

Waste glass fibre used as a loose insulation won't burn but can be dusty, settle and move about.

Wool used as loose insulation is made from low-grade natural wool or waste clothing. It can also be dusty, and will burn in an established fire. If your roof leaks, wool and paper insulation won't dry as well as mineral fibre and may encourage mould.

When getting quotes, you need to compare the weight and thickness of the fill. How many kilograms per square metre (this is the density) are needed to get the right R value? Ask how many bags of insulation are needed and check they are all used.

The Fire Service has complained about macerated paper in the past, saying it can smoulder and fall onto a firefighter trying to gain access through the ceiling to a burning roof space. The same could apply to wool used as a loose fill.

Polyester and wool

Polyester and wool come in a roll ready to run out in a roof space, or cut into segments for fitting between the framing timbers in your walls or ceiling.

Polyester, wool and blends of these are relatively recent additions. They are more expensive than glass fibre, but more pleasant to handle and won't cause skin irritation. But they are not as easy to cut.

Reflective foil

Foil has been used for many years for underfloor insulation. A ban on the installation of foil insulation into residential buildings, and the repair of existing foil insulation, came into force on 1 July 2016.

Since 2005, five people have died after being electrocuted when foil insulation they were installing came into contact with electrical wiring.

Spray foam insulation

As the name suggests, spray foam insulation is applied using a spray gun. Once the foam makes contact with the surface, it expands and hardens. If applied correctly, there’s much less airflow around the insulation when compared to other products. The thermal performance is affected by both the coverage and thickness of the application.

Installing spray foam is a specialist job, so you can’t do it yourself. However, you can still check that the foam is installed to the correct thickness and that there aren’t any gaps around the edges.

For more information on insulation material characteristics, see Beacon Pathway's report "Thermal Insulation in NZ homes" (pp. 16-18)